SEARCH SITE

Meet Emissions Requirements for Autoclaves and Ovens

New emissions regulations like SCAQMD Rule 1147 require tighter control of emissions from equipment like autoclaves and ovens. Failure to meet the new requirements could impact production for many manufacturers.

Our experienced team can help you navigate the new emissions requirements and make sure your equipment continues operating efficiently.

We Offer Complete Testing, Tuning, and Retrofit Services:

- Initial emissions testing to see if your equipment meets the new 30 ppm (autoclaves) or 20 ppm (ovens) NOx requirements

- Skilled tuning of your burners and combustion systems to optimize emissions performance

- Upgrade projects to install new low-NOx burners or other equipment to meet compliance

- Ongoing testing services to validate emissions levels

Keep Production Running Smoothly

Rule 1147 provides time windows to get equipment into compliance. But you need to act fast to avoid disruptions. As an experienced service provider for top OEMs, we have the expertise to quickly test your equipment and perform necessary upgrades.

We work on all makes and models.

Trust Our Decades of Industry Experience

Our engineering team has worked on SCAQMD compliance for over 25 years. We know what's required and can think outside the box to get systems approved. Lean on our team to cost-effectively meet the new emissions regulations. We're here to help you continue operating at full capacity after the rule changes.

Contact us today to discuss your options!

Autoclave Consulting

If you’re setting up a new production facility and require help on autoclave and equipment specifications, ASC can help.

Composite Autoclave and composite oven evaluation

If you have problems with your existing autoclave or oven and would like to have an expert opinion, then contact ASC and we can set up a consulting visit to analyze your production needs and your existing composite bonding systems. We will generate a detailed report of findings and recommendations for future upgrades and improvements.

Specification development

ASC's professional Mechanical and Electrical Engineers, Sales Team, and Service Technicians are experienced composite autoclave and composite oven experts. We are here to help when you need it. Let us help you develop technical procurement specifications for your next autoclave, oven, and other thermal process equipment. You will be able to rest assured your next autoclave or oven will meet and exceed your requirements.

Design Engineering

Design Engineering

Custom Design Engineering services

ASC has more than 30 engineers on staff. From electrical engineers, mechanical engineers, to control engineers and to our software development team, we are ready to handle all your custom design engineering needs. Contact us and let us know how we can help you.

New machinery – concept to build

ASC can develop new and custom autoclaves and ovens from the ground up. Just let us know what you want it to do, and ASC’s design engineers can make your idea a reality.

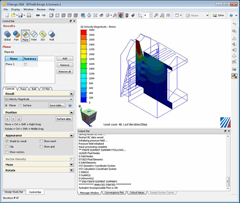

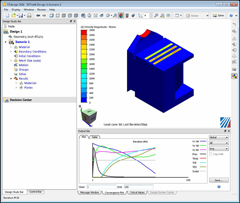

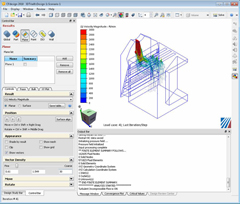

CFD Analysis

Don’t learn too late that your process won’t work

ASC has years of experience in CFD (Computational Fluid Dynamics) analysis to support our autoclave and oven design and manufacturing. We’ve recently made this experience available to our customers for tooling and equipment validation.

Putting a large tool into an oven might not work. With ASC’s CFD analysis experience, we can simulate your tool in the equipment and let you know how it will heat and cool. We have taken more than a dozen contracts with major aerospace companies to validate equipment and tooling.

Preventive Maintenance

Preventive Maintenance

for Autoclaves & Ovens

ASC has a full-time service staff that can provide scheduled, preventive maintenance on your composites autoclaves and composites ovens

Autoclave and oven preventive maintenance

Contact ASC and we’ll set up a specialized PM service for your composite bonding equipment. This is typically a bi-annual or annual visit that includes a detailed list of checks, adjustments, and tuning to keep your equipment in working order.

AUSTRIA

AUSTRIA BRAZIL

BRAZIL CHINA

CHINA FRANCE

FRANCE GERMANY

GERMANY ITALY

ITALY JAPAN

JAPAN LATIN AMERICA

LATIN AMERICA RUSSIA

RUSSIA SOUTH KOREA

SOUTH KOREA SPAIN

SPAIN UK

UK USA

USA