SEARCH SITE

Glass Laminating Autoclave Systems

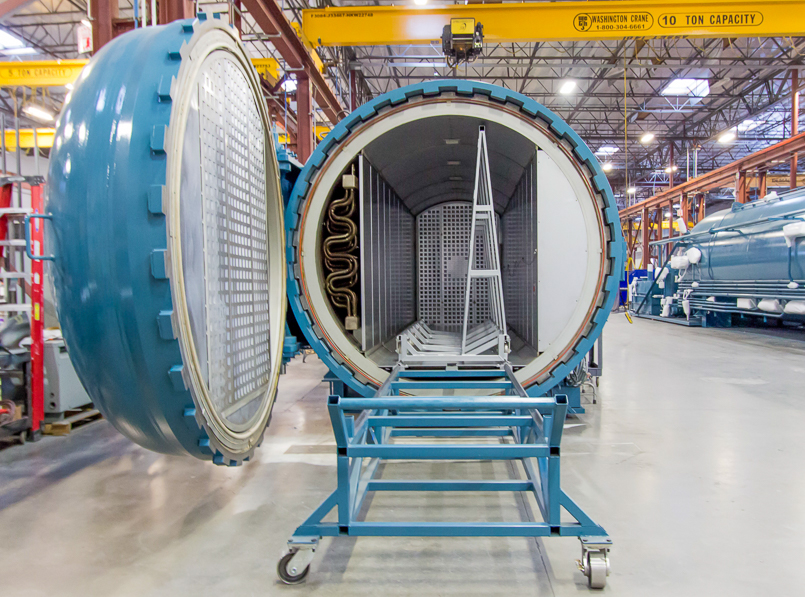

The Econoclave GLS autoclave with our flagship CPC controls is engineered specifically for laminating architectural, automotive, ballistic, and safety glass worldwide. With robust construction, precision temperature control, and seamless integration with major lamination lines, the Econoclave GLS delivers maximum efficiency for glass bonding and curing.

ASC Econoclave GLS autoclave for laminated glass manufacturing.

ASC's Econoclave GLS is the most advanced glass-laminating autoclave in the world. The GLS reduces cycle time by utilizing advanced air-delivery to improve heat transfer into the laminate. All GLS units also come standard with ASC's proven CPC computer control system.

Laminated Glass

Laminated glass is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB), between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic "spider web" cracking pattern when the impact is not enough to completely pierce the glass.

Laminated glass is normally used when there is a possibility of human impact or where the glass could fall if shattered. Skylight glazing and automobile windshields typically use laminated glass. In geographical areas requiring hurricane-resistant construction, laminated glass is often used in exterior storefronts, curtain walls, and windows. The PVB interlayer also gives the glass a much higher sound insulation rating, due to the damping effect, and also blocks 99% of incoming UV light.

Architectural Laminated Glass

Laminated Glass Stairs

In the manufacturing process, the assembly of float glass and PVB are laminated together and then placed in an autoclave. A typical autoclave lamination cycle ramps pressure to 180 psi (12.4 bar) and temperature to 280 °F (137 °C). The cycle completes after 30-60 minutes. Cooling is ramped down at a controlled rate in order to reduce thermal stress and cracking. Vacuum bagging of parts is also used to help remove bubbles and improve overall part quality.

AUSTRIA

AUSTRIA BRAZIL

BRAZIL CHINA

CHINA FRANCE

FRANCE GERMANY

GERMANY ITALY

ITALY JAPAN

JAPAN LATIN AMERICA

LATIN AMERICA RUSSIA

RUSSIA SOUTH KOREA

SOUTH KOREA SPAIN

SPAIN UK

UK USA

USA