SEARCH SITE

Autoclaves for Ballistic Armor

Ballistic armor is fabricated from a mix of composite materials, steel, silica, and ceramics. In order to increase the quality of the final product, most armor must be bonded and cured in composite curing autoclaves.

ASC's ballistic-capable Econoclave is used to manufacture the composite structures that are ultimately assembled into the final delivered armor.

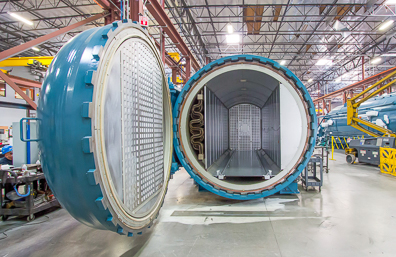

Interior of Ballistic Glass Laminating Econoclave

Econoclave for Ballistics manufacturing

As the use of IEDs (improvised explosive device) increased during the recent conflicts in Iraq and Afghanistan, the US and International military units saw the immediate need to improve both the body armor given to each soldier and the armor assembled into personnel vehicles. The goal was to increase survivability, and the result was a focused plan to develop and manufacture more and better armor

ASC's autoclaves and control systems have become instrumental in the production of ballistic armor. Our high-pressure composite curing autoclave system, known worldwide as the Econoclave, is ballistic-capable, rated for high-pressure, and is used by the world's largest armor producers.

AUSTRIA

AUSTRIA BRAZIL

BRAZIL CHINA

CHINA FRANCE

FRANCE GERMANY

GERMANY ITALY

ITALY JAPAN

JAPAN LATIN AMERICA

LATIN AMERICA RUSSIA

RUSSIA SOUTH KOREA

SOUTH KOREA SPAIN

SPAIN UK

UK USA

USA